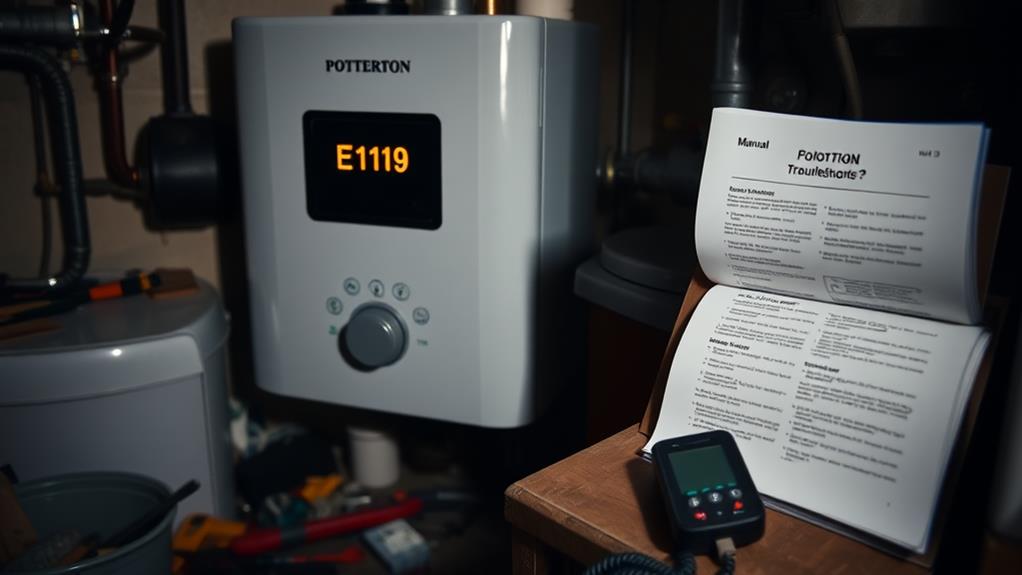

When you see the E119 error code on your Potterton boiler, it means there’s a low-pressure problem, typically due to water loss. Check your boiler’s pressure gauge; it should read between 1.0 and 1.5 bar when cold. If it’s lower, try bleeding radiators to remove trapped air or inspect for leaks in pipes or radiators. Adjust the pressure using the filling loop, ensuring you close the valves after reaching the desired pressure. Persistent issues may require a professional. Regularly monitoring your pressure gauge is key to avoiding further complications. Discover more to potentially save yourself from costly repairs.

Key insights

- The E119 error indicates low pressure in Potterton boilers, usually due to water loss in the system.

- Ideal pressure for a Potterton boiler is between 1.0 and 1.5 bar when cold.

- Use the filling loop to add water if pressure falls below recommended levels.

- Frequent E119 errors or pressure fluctuations may signal leaks or component failures.

- Professional assistance ensures safety and compliance with gas appliance regulations.

Understanding the E119 Error

The E119 error code on a Potterton boiler indicates a low-pressure issue within the system, often caused by a loss of water. This error is a clear indication of the significance of regular boiler service to maintain ideal boiler pressure, which is crucial for efficient operation. Low pressure can lead to inadequate heating and potential damage.

To address this, you’ll want to start by checking the pressure gauge. Ideally, it should read between 1.0 and 1.5 bar. If it’s below this range, you must repressurize the system. One of the essential boiler maintenance tips is to routinely inspect and verify the pressure relief valve is functioning correctly. This valve prevents excessive pressure buildup, safeguarding the system from potential hazards. If the valve is faulty, it might contribute to pressure loss, necessitating immediate attention.

Additionally, you should regularly bleed radiators to remove trapped air, which can impact pressure levels. This process involves opening the radiator bleed valve to release air until water begins to flow steadily. By keeping an eye on the pressure and performing these maintenance tasks, you can help prevent the E119 error from disrupting your heating system.

Causes of Low Water Pressure

Addressing the E119 error involves understanding the root causes of low water pressure in your Potterton boiler system. This error often signals that your boiler’s water pressure has dropped below the required threshold. To effectively tackle this issue, you need to identify potential causes. Regular maintenance is essential for early detection and resolution of such issues, enhancing the longevity and efficiency of your boiler system.

- Leaks in the System: Even minor leaks from pipes or radiators can lead to a significant drop in water pressure. Regularly inspect your system for any damp spots or visible drips.

- Faulty Pressure Gauge: The pressure gauge is important for monitoring the system’s water pressure. If it malfunctions, it might display incorrect readings, leading you to believe there’s a pressure issue when there isn’t. Confirm the gauge is functioning and calibrated correctly.

- Air in the System: Air trapped within the radiators can displace water, resulting in reduced pressure. Bleeding radiators can help remove excess air, thereby restoring ideal pressure levels.

Understanding these causes helps you maintain your boiler’s efficiency and avoid recurrent E119 errors. Regular maintenance and monitoring of the pressure gauge are essential in preventing low water pressure, guaranteeing your Potterton boiler operates smoothly.

Checking Boiler Pressure

When it comes to ensuring your Potterton boiler operates efficiently, checking boiler pressure is essential. Regular maintenance, like the plant room maintenance in commercial buildings, is key to avoiding costly repairs and system downtime. Maintaining the correct pressure is critical for ideal performance and avoiding issues like the E119 error code.

Start by locating the pressure gauge, usually found on the front panel of your boiler. This gauge is important in monitoring the system’s pressure, which should typically read between 1.0 and 1.5 bar when the boiler is cold. Just as routine inspections are critical in a plant room setting to identify leaks and monitor fuel levels, regular inspection of your boiler’s pressure gauge can prevent potential system shutdowns.

If the pressure falls below the recommended level, it can lead to inefficient heating and potential system shutdowns. Regularly inspecting the pressure gauge is a key boiler maintenance tip to prevent these problems. To check the pressure, simply glance at the gauge and note the reading. If it’s outside the ideal range, adjustments might be necessary to bring it back to normal.

DIY Solutions to Try

Many homeowners encounter the E119 error code and can resolve it with some straightforward DIY solutions. This code often indicates a drop in pressure, and addressing it is vital for proper boiler maintenance. Regular maintenance and checks not only safeguard your boiler operations but also prevent costly breakdowns and operational disruptions Comprehensive maintenance. Start by checking the pressure gauge on your Potterton boiler; it should ideally be between 1 and 1.5 bar.

If it’s below this range, you need to restore pressure to guarantee your boiler meets current safety and environmental standards, enhancing reliability, and reducing the likelihood of unexpected failures. Here’s how you can do this:

- Locate the Filling Loop: Identify the filling loop, usually a silver, flexible pipe with a valve at each end, beneath the boiler. Confirm both ends are securely connected to the boiler’s system.

- Open the Valves: Turn both valves slowly to allow cold water into the system. As you do this, monitor the pressure gauge closely. Once it reaches the desired level (around 1.5 bar), close the valves tightly to prevent over-pressurization.

- Check for Pressure Relief: After adjusting the pressure, it’s important to verify that the pressure relief valve isn’t leaking. A leak might cause pressure to drop again, requiring further attention.

These simple steps can often clear the E119 error, enhancing your boiler’s efficiency and prolonging its lifespan. Regular boiler maintenance will help prevent future issues.

When to Call a Professional

When you encounter persistent E119 error codes or notice irregular noises from your Potterton boiler, it’s essential to call a professional. These signs often indicate serious issues such as potential gas leaks or carbon monoxide poisoning, both of which can be serious safety hazards as outlined in the Commercial Gas Safety Certificate requirements. They also require expert assessment to guarantee safety and compliance with regulations. Attempting complex repairs on your own might exacerbate the problem or void warranties, so professional intervention is recommended.

Signs of Serious Issues

Encountering an E119 error code on your Potterton boiler might indicate underlying issues that require professional attention. While some minor problems can be addressed through regular boiler maintenance, certain signs suggest that a more serious issue is at play. Monitoring the pressure gauge is essential, as persistent low pressure could mean there’s a leak or a component failure that needs a professional fix.

When facing the E119 error, look out for these serious signs:

- Pressure fluctuations: If the pressure gauge shows erratic readings, it often signals a deeper systemic problem. This inconsistency might lead to inefficient heating or even system shutdown.

- Continuous resetting: If you find yourself frequently resetting the boiler to clear the error, it indicates a persistent malfunction. Consistent errors can stress the system and lead to more severe damage if not addressed.

- Water leaks: Visible water leaks around the boiler or associated pipework suggest a breach in the system, which can worsen over time and potentially damage your property.

These signs suggest that the E119 error isn’t a simple fix. Calling a professional guarantees your boiler operates safely and efficiently, preventing potential hazards and costly repairs.

Safety and Compliance Concerns

Amidst dealing with an E119 error on your Potterton boiler, it’s crucial to prioritize safety and compliance by knowing when to call a professional. Boilers involve complex systems and high-pressure components, making it critical to adhere to safety regulations and compliance standards. If your boiler’s pressure gauge consistently reads outside the safe range or if you notice unusual noises, stop troubleshooting and contact a certified technician.

Safety regulations mandate that only qualified professionals should handle gas appliances. Attempting to fix the issue yourself could compromise the appliance’s integrity and void any warranty or insurance coverage. Professionals are trained to diagnose and resolve errors efficiently while guaranteeing the boiler meets all compliance standards.

Moreover, a professional can perform a thorough inspection to identify any underlying issues that might contribute to recurring E119 errors. They have the tools and expertise to implement a safe solution, reducing the risk of future malfunctions. Remember, your safety and your household’s safety are paramount. Don’t hesitate to seek help when dealing with gas and high-pressure systems. A professional guarantees your boiler operates safely, efficiently, and in accordance with all applicable safety regulations and compliance standards.

Preventing Future Issues

Guaranteeing your Potterton boiler operates smoothly requires adopting a proactive maintenance regimen, much like the routine upkeep recommended for commercial heat pumps. Regular boiler maintenance is essential to prevent recurring E119 error codes, which often stem from pressure regulation issues. By scheduling annual inspections, you can identify potential problems before they escalate, similar to how preventative maintenance helps avoid costly repairs and downtime in heat pump systems. Here’s a strategic approach to preventing future issues:

- Monitor Boiler Pressure: Check the pressure gauge regularly. The ideal range is between 1 and 1.5 bar when the system is cold. If the pressure is consistently outside this range, it could indicate a leak or a faulty pressure relief valve.

- Bleed Radiators: Air trapped in radiators can cause pressure fluctuations. Bleeding radiators at least once a year guarantees peak performance and pressure stability. This simple task can prevent unnecessary strain on your boiler.

- Inspect Components: Regularly examine key components like the expansion vessel, pressure relief valve, and filling loop. Wear and tear can occur, so replace any parts showing signs of damage. This preventive measure safeguards against sudden breakdowns.

Frequently Asked Questions

Can the E119 Error Code Affect My Heating Schedule?

If you encounter the E119 error code, it can indeed disrupt your heating schedule. This error typically indicates a pressure issue, affecting your boiler’s functionality. When pressure is too low, your boiler might not operate effectively or at all, causing interruptions in your heating program. To maintain peak boiler functionality and guarantee your heating schedule remains consistent, promptly address the pressure problem by checking and adjusting the system as needed.

How Does the E119 Error Code Impact My Energy Bills?

When your heating system’s error impacts energy efficiency, you’ll likely see cost implications in your energy bills. The system works harder to maintain desired temperatures, consuming more energy. This inefficiency leads to higher costs, as more fuel is burned to compensate for the error. Regular maintenance can prevent such issues, ensuring peak performance. Checking and resolving error codes promptly helps maintain energy efficiency, minimizing unnecessary expenses on your energy bills.

Is the E119 Error Code Common in All Potterton Models?

You might wonder if the E119 error code is common across all Potterton models. It’s not universal; different models can have varying susceptibility to this issue. Familiarize yourself with specific Potterton model differences to better understand potential errors. To address the E119 error, use E119 troubleshooting tips: check system pressure, inspect for leaks, and guarantee the filling loop is closed. Regular maintenance can prevent reoccurrence in susceptible models.

Can Weather Conditions Trigger the E119 Error Code?

Weather influences can indeed trigger certain boiler error codes. When you’re troubleshooting an error, consider how temperature drops may affect pressure levels. Cold weather can cause water pressure to drop, leading to error codes related to low pressure. Wind may impact external flues, causing blockages or drafts that affect boiler performance. Always check for any weather-related changes before diving deeper into more complex error troubleshooting.

What Are the Risks of Ignoring the E119 Error Code?

Imagine a ticking time bomb in your home, slowly counting down with every ignored warning. Ignoring an error code poses risks like inefficient heating or complete system failure. To avoid this, regularly follow maintenance tips like bleeding radiators and checking pressure. Implement troubleshooting steps such as resetting the boiler and inspecting connections. Keeping everything in check guarantees safety, efficiency, and longevity, preventing costly repairs and maintaining a warm, comfortable environment.

Summary

In tackling the Potterton boiler E119 error, you’ve learned that maintaining ideal water pressure is key. Did you know that nearly 25% of boiler issues stem from low water pressure? By regularly checking and adjusting your boiler’s pressure, you can prevent this common problem. Remember, DIY solutions work wonders for minor issues, but don’t hesitate to call a professional for complex problems. With regular maintenance, you’ll guarantee your boiler runs efficiently and avoid future disruptions.