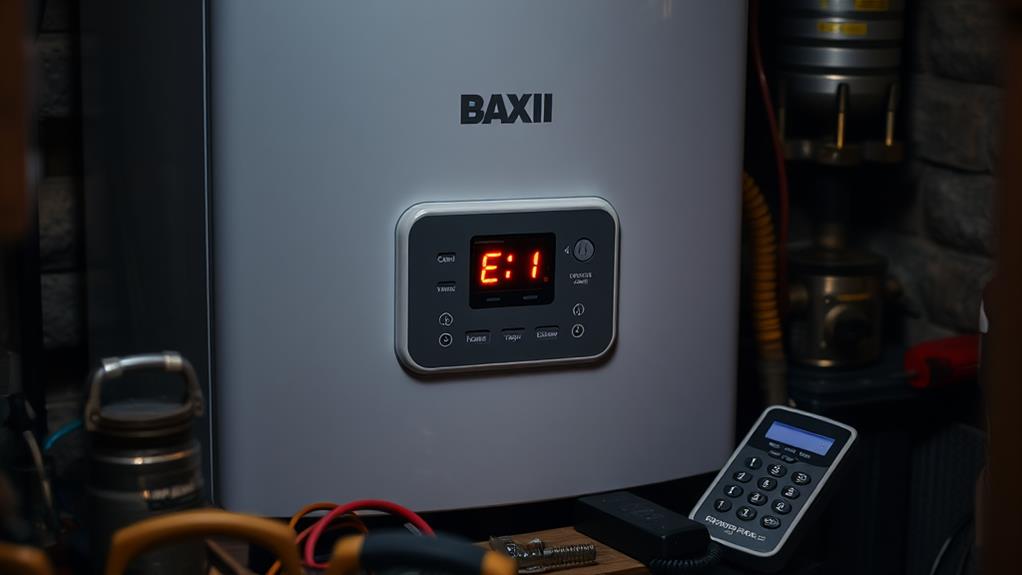

You’re dealing with a Baxi Boiler E1 error code, signaling low water pressure, which often stems from leaks or faulty pressure valves. Check the pressure gauge first; it should be between 1.0 and 1.5 bar. Trapped air or blockages can also cause this error. Start troubleshooting by inspecting for leaks and ensuring unobstructed water flow. You might need to adjust the water pressure using the filling loop or release air from the system. If these steps don’t resolve the issue, a professional inspection might be necessary. Explore further if you’d like insights into preventing future occurrences.

Key insights

- The E1 error code on a Baxi boiler indicates low water pressure, requiring immediate attention to prevent damage.

- Check the pressure gauge; it should read between 1.0 and 1.5 bar when cold to avoid the E1 error.

- Increase pressure by opening the filling loop if the gauge reads below 1 bar to resolve the E1 error.

- Regular maintenance, including inspections and pressure checks, can prevent future E1 error occurrences.

- Persistent E1 errors despite troubleshooting indicate a need for professional assessment and servicing.

Understanding the E1 Error Code

Encountering an E1 error code on your Baxi boiler can be frustrating, but understanding its implications is important for efficient troubleshooting. The E1 error typically signals a low water pressure issue within the boiler system. This error code is a significant diagnostic tool, alerting you to a problem that, if left unresolved, might lead to more significant complications. As part of plant room maintenance, regular checkups of boiler systems can help identify such issues early, avoiding costly repairs or replacements.

When the E1 error appears, your first step should be to check the boiler’s pressure gauge. It should ideally read between 1.0 and 1.5 bar when the system is cold. If the pressure is below this range, your boiler might not function correctly, leading to the E1 error. Regularly monitoring and maintaining the appropriate pressure levels is an essential aspect of boiler maintenance, helping to avert potential issues before they arise. It’s also important to note that routine inspection and servicing can optimize your boiler’s efficiency and longevity, reducing energy consumption and operational costs.

Additionally, familiarize yourself with your Baxi boiler’s manual to understand specific instructions related to the E1 error. This knowledge empowers you to address minor issues promptly, ensuring your boiler remains reliable and efficient in delivering heating and hot water.

Common Causes of E1 Error

Several factors might cause the E1 error on your Baxi boiler, primarily revolving around pressure-related issues. Low water pressure is a frequent culprit, often resulting from leaks or a faulty pressure relief valve. Maintaining the ideal pressure level is vital, as deviations can trigger the E1 error. Regularly checking your boiler’s pressure gauge is a fundamental boiler maintenance tip to prevent such common heating issues.

Engaging a professional commercial boiler service can help identify and address these issues early, preventing costly repairs and maintaining ideal boiler performance. They can carry out thorough checks and tests, ensuring your boiler is in the best working condition.

Another cause could be trapped air in the system. When air becomes trapped in the radiator or pipes, it can disrupt the water flow, leading to pressure fluctuations. Bleeding your radiators can help release any trapped air, ensuring efficient boiler operation. This simple maintenance step can greatly reduce the likelihood of encountering the E1 error.

Sediment buildup within the boiler can also contribute to the problem. Over time, mineral deposits can accumulate, obstructing water flow and affecting pressure levels. To mitigate this, consider periodic flushing of the system. This not only prevents pressure issues but also enhances the overall efficiency of your boiler.

Regularly inspecting and maintaining your boiler, addressing leaks promptly, and ensuring clean, air-free pipes are essential practices to minimize the occurrence of the E1 error and other common heating issues.

Troubleshooting the E1 Code

Identifying the root cause of the E1 error on your Baxi boiler is the first step to restoring ideal function. Start by checking the pressure gauge on the boiler. If the pressure is below 1 bar, it could be triggering the E1 error. To resolve this, locate the filling loop—usually a silver flexi hose—and slowly open the valves to increase the pressure to the recommended 1.5 bar. This simple boiler maintenance step often resolves the error, guaranteeing the high reliability and efficiency that Baxi boilers are known for.

If pressure isn’t the issue, examine the temperature sensor and wiring connections. Faulty sensors can falsely trigger errors, disrupting boiler operation. Verify all connections are secure and consider replacing the sensor if it appears damaged or worn. An important part of boiler maintenance is confirming that all components, including sensors and wiring connections, are in good condition as they are integral to the boiler’s peak performance.

You should also inspect the air vent and release any trapped air to prevent the error code from recurring. Proper ventilation is key in promoting efficient operation and error resolution. Finally, verify that there’s no obstruction in the condensate pipe. Blockages can cause pressure imbalances, leading to an E1 error. Clear any debris from the pipe to maintain peak performance. If these steps don’t resolve the E1 error, consulting a professional technician is advisable for more complex issues.

Preventing Future E1 Errors

To prevent future E1 errors on your Baxi boiler, it’s vital to establish a routine maintenance schedule. Start by regularly checking the boiler’s water pressure and verify it’s within the manufacturer’s recommended range, typically between 1.0 and 1.5 bar. Low pressure can trigger the E1 error, so it’s necessary to top up as needed. Regular inspections of your boiler can catch small issues before they escalate, prolonging the lifespan of the heating system through consistent upkeep. These inspections can be carried out by Gas Safe registered engineers, who are trained to guarantee compliance with safety standards.

Inspect the pressure relief valve and expansion vessel for any leaks or signs of wear, as these components are important for maintaining proper pressure levels. Incorporate system upgrades as part of your maintenance routine. Consider the installation of a magnetic filter to capture circulating debris and prevent blockages. This simple upgrade can enhance your boiler’s efficiency and reduce the likelihood of error codes.

In addition to this, verify the condensate pipe is insulated, especially during colder months, to prevent freezing, which can lead to pressure issues. Review your boiler’s user manual for specific maintenance tips tailored to your model. Regularly clean the system’s heat exchanger and verify the air vents are unobstructed. By following these steps, you’ll maintain peak performance, support environmental sustainability, and greatly reduce the risk of encountering an E1 error, prolonging the lifespan of your Baxi boiler.

When to Contact a Professional

One key moment to contact a professional for your Baxi boiler is when you notice persistent E1 error codes despite having followed standard troubleshooting procedures. Recognising the importance of a Commercial Gas Safety Certificate, it’s vital to understand that while basic troubleshooting can address simple issues, persistent errors may signify deeper, complex problems necessitating expert intervention. Ignoring these signs can compromise your boiler’s efficiency, leading to significant damage and even jeopardising your safety compliance.

A professional can conduct extensive Baxi maintenance checks, guaranteeing that components like the pressure sensor, heat exchanger, and valves are functioning correctly. They’ll perform thorough boiler safety checks, identifying potential hazards such as gas leaks or pressure faults that aren’t evident to the untrained eye. Attempting to resolve these issues without expertise not only risks further damage but also endangers your safety.

Moreover, if your boiler is under warranty, professional servicing might be a requirement to maintain coverage. By contacting a professional, you ascertain that your Baxi boiler operates safely, efficiently, and in compliance with manufacturer guidelines. This proactive approach not only resolves current issues but also helps prevent future errors, keeping your home warm and your boiler in ideal condition.

Frequently Asked Questions

Can an E1 Error Affect the Overall Efficiency of My Baxi Boiler?

An E1 error can impact your boiler’s performance by reducing its efficiency. When this error occurs, immediate error troubleshooting is essential to prevent further complications. Ignoring it might lead to higher energy consumption and inconsistent heating. You should consult your boiler’s manual or a professional technician to address the issue promptly. By resolving the E1 error, you guarantee your boiler operates smoothly and maintains peak performance levels.

How Long Does It Typically Take to Resolve an E1 Error on a Baxi Boiler?

When you’re facing an E1 error, troubleshooting can vary based on the issue’s complexity. Typically, resolving this error involves checking pressure levels or addressing a sensor malfunction. The boiler repair timeline can range from a quick fix in under an hour to a more extended period if parts need replacing. Verify you have the right tools and follow the manual’s instructions, or consult a professional for efficient resolution.

Are There Any Specific Models of Baxi Boilers More Prone to E1 Errors?

Like a storm on the horizon, certain Baxi models can be more prone to frequent errors. You might find that older models, such as the Baxi Duo-tec and Platinum, experience higher error frequency due to wear over time. While newer models typically boast improved reliability, regular maintenance can greatly reduce error occurrences. It’s wise to consult the manual and follow maintenance schedules to keep your boiler running smoothly.

What Parts of the Boiler Are Most at Risk When an E1 Error Occurs?

When you see an E1 error, focus on the pump and circuit components. Pump failure can happen due to blockages or mechanical issues, which might stop water circulation and cause overheating. Circuit issues often involve faulty wiring or poor connections, affecting the boiler’s operation. Inspect these areas for signs of wear or damage. By addressing pump and circuit problems promptly, you can prevent potential damage and maintain your boiler’s efficiency.

Can an E1 Error Void My Baxi Boiler Warranty?

When dealing with error codes, you might wonder if your warranty is at risk. For the E1 error, check your warranty’s fine print, as warranty implications depend on factors like boiler maintenance. Poor maintenance can void warranties, so guarantee regular servicing. If the error results from a covered defect, your warranty should remain intact. Always document repairs and maintenance to support any warranty claims. Keeping up with maintenance safeguards your warranty.

Summary

Think of your Baxi boiler as the heart of your home, and the E1 error is its way of signaling distress. By understanding and troubleshooting this error, you’re performing a crucial check-up, ensuring your home’s lifeblood flows smoothly. Regular maintenance can prevent future disruptions, but remember, when the pulse falters beyond your expertise, it’s time to call a professional. Keep your system healthy, and it will reward you with warmth and comfort.