The most expensive part of a boiler is typically the burner assembly. It plays a critical role in the combustion process, impacting functionality and efficiency. High-quality materials and complex designs drive up its cost considerably. Neglecting maintenance on the burner can lead to higher replacement costs and decreased performance. Understanding the intricacies of the burner helps you grasp its importance in overall boiler operation. You'll discover more about boiler components and their costs shortly.

Key insights

- The burner assembly is often the most expensive component due to its complexity and critical role in combustion efficiency.

- Heat exchangers can also be costly, as their materials and design significantly influence boiler efficiency and longevity.

- Control systems, including PLCs and sensors, represent 20% to 30% of the total boiler investment, impacting overall costs significantly.

- The combustion chamber's construction materials can drive up expenses, especially if high-quality, corrosion-resistant materials are used.

- Regular maintenance of these components is essential to prevent costly replacements and ensure optimal performance over time.

Understanding Boiler Components

Understanding the components of a boiler is essential for identifying its most expensive parts. Boilers can be categorized into various types, such as fire-tube, water-tube, and electric, each featuring distinct operational principles and component materials. The materials used in these components often influence the overall costs. For example, stainless steel and copper are more expensive than carbon steel, reflecting their durability and corrosion resistance. Key components to examine include the burner assembly, combustion chamber, and control systems, as these often incur significant expenses due to their complexity and materials. By analyzing the specific boiler type and its component materials, you can better gauge which parts contribute most to the overall investment and maintenance costs associated with boiler systems. Regular commercial boiler service is crucial for maintaining these components and ensuring their longevity.

The Role of the Boiler Heat Exchanger

The heat exchanger plays an essential role in a boiler's efficiency and performance. It transfers heat from the combustion gases to the water, guaranteeing optimal energy use. Understanding different heat exchanger types can greatly impact your boiler's efficiency ratings. Here are three key aspects to take into account:

- Material Quality: Higher-quality materials can withstand corrosion, enhancing longevity and efficiency.

- Design Efficiency: Advanced designs maximize heat transfer, reducing energy consumption.

- Maintenance Needs: Regular upkeep guarantees that the heat exchanger operates at peak efficiency, preventing costly breakdowns. Additionally, regular maintenance of the entire boiler system is crucial for ensuring safety and compliance with regulatory requirements.

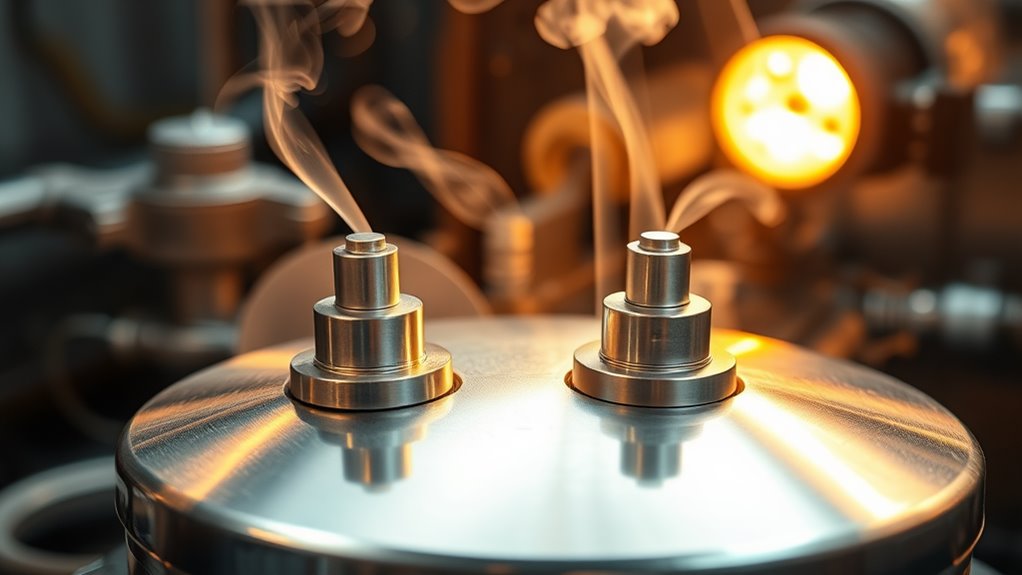

The Importance of the Boiler Burner

The boiler burner is essential for ensuring ideal functionality and efficiency, as it directly impacts the combustion process. If you neglect its maintenance, you might face significant replacement costs and reduced system performance. Understanding the burner's role helps you make informed decisions about upkeep and upgrades. Regular inspections for unusual noises can also help in early detection of potential burner issues, preventing costly repairs down the line.

Burner Functionality and Efficiency

While many components of a boiler contribute to its overall performance, the burner stands out as an essential element that directly influences both functionality and efficiency. Its design determines how well the boiler meets efficiency standards, impacting your energy consumption and operating costs.

Consider these key factors:

- Combustion Control: An efficient burner optimizes fuel use, reducing waste and lowering emissions.

- Heat Transfer: Proper burner design enhances heat distribution, maximizing your system's effectiveness.

- Safety Features: Advanced burners incorporate safety mechanisms, ensuring reliable operation and peace of mind.

Investing in a high-quality burner not only boosts efficiency but also extends the lifespan of your boiler, making it an essential component worth your attention. Additionally, regular maintenance is crucial for ensuring optimal burner performance and preventing potential issues that could disrupt operation.

Replacement and Maintenance Costs

When considering the longevity and efficiency of your boiler, understanding replacement and maintenance costs is vital, especially regarding the burner. The burner greatly impacts your boiler's lifespan and overall energy efficiency. Regular maintenance can prevent costly breakdowns and extend the life of your burner, ultimately saving you money. However, if the burner fails, replacement costs can be substantial, often comprising a large portion of your boiler's total expenses. Investing in high-quality components and professional servicing can mitigate future costs, ensuring the best performance. By prioritizing maintenance and monitoring the burner's condition, you can enhance your boiler's energy efficiency and minimize long-term financial burdens. Ultimately, a well-maintained burner is essential for maximizing your system's operational efficiency and lifespan. Additionally, regular maintenance can help prevent common error codes that may arise from burner issues.

Evaluating the Cost of Boiler Controls

When evaluating the cost of boiler controls, you need to contemplate multiple factors, including control system components and their respective prices. Installation and programming costs can also greatly impact your overall budget, so it's vital to factor those in. Additionally, ongoing maintenance and repair expenses will affect your long-term investment, making a thorough assessment essential. Regular inspections are crucial for ensuring commercial gas safety compliance, which can help prevent costly repairs in the future.

Control System Components

Control system components account for a significant portion of a boiler's overall cost, often representing 20% to 30% of the total investment. Investing in control system upgrades not only enhances performance but also maximizes automation benefits, leading to improved efficiency and reduced operational costs.

Consider the following key components:

- Programmable Logic Controllers (PLCs) – These sophisticated devices manage various boiler functions, ensuring safety and efficiency.

- Sensors and Transmitters – Essential for real-time data collection, they help optimize system performance.

- User Interface Panels – These provide operators with critical information and control over the boiler system, enhancing user experience.

Evaluating these costs is crucial for achieving long-term savings and operational reliability in your boiler system. Additionally, compliance with safety regulations is critical for the effective operation of control systems, ensuring that they function reliably and safely.

Installation and Programming Costs

While many focus on the upfront costs of boiler systems, installation and programming expenses can considerably impact the total investment. You might encounter installation challenges, such as integrating new controls with existing infrastructure or ensuring proper placement for peak efficiency. These factors can inflate labor costs and timeframes, leading to higher overall expenses.

Programming complexity is another critical consideration. Advanced control systems require skilled technicians to configure settings accurately, which can further drive up costs. Inadequate programming may lead to inefficiencies, necessitating additional adjustments that add to your budget. Ultimately, understanding these installation and programming costs is essential for evaluating the true financial commitment of your boiler system and ensuring long-term operational efficiency. Additionally, considering energy-efficient heating and cooling solutions can help you make an informed choice that balances upfront costs with future savings.

Maintenance and Repair Expenses

Maintenance and repair expenses can greatly impact the long-term costs associated with boiler controls. To guarantee your boiler operates efficiently and extends its lifespan, you need to contemplate several factors:

- Repair Frequency: Frequent repairs can indicate underlying issues, leading to higher costs and downtime.

- Parts Replacement: Aging components may require replacement, considerably increasing your expenses over time.

- Regular Maintenance: Investing in preventive maintenance can reduce repair frequency and extend your boiler's lifespan. Additionally, conducting a commercial power flush can significantly enhance system efficiency and prevent costly breakdowns.

The Impact of Installation and Labor Costs

When considering the overall expense of a boiler, installation and labor costs often emerge as significant factors that can dramatically affect your budget. The choice of installation techniques plays a vital role; skilled technicians can utilize efficient methods that minimize both time and material waste, thereby reducing overall costs. However, varying labor rates based on geographical location and technician expertise can lead to substantial differences in your final expenditure. For instance, hiring a seasoned professional may incur higher upfront costs, but their precision can prevent future complications. It is important to obtain detailed quotes, breaking down installation and labor charges, to fully understand how these costs contribute to your boiler's total expense. This proactive approach helps you manage your budget effectively. Additionally, investing in energy-efficient heating systems can lead to lower operational costs over time, further influencing your financial planning.

Long-Term Maintenance Expenses

To guarantee your boiler operates efficiently over time, you must consider long-term maintenance expenses as an essential aspect of ownership. Investing in preventive maintenance not only enhances performance but also guarantees long-term savings. Here are three key expenses to keep in mind:

- Regular Inspections: Scheduled check-ups help identify potential issues early, preventing costly repairs later.

- Replacement Parts: Over time, components wear out, and timely replacements can maintain efficiency and safety.

- Cleaning Services: Routine cleaning prevents buildup and inefficiencies, further extending your boiler's lifespan.

Frequently Asked Questions

How Does Boiler Size Affect Overall Costs?

Boiler size markedly impacts overall costs. A properly sized boiler enhances boiler efficiency, which can lower your energy bills over time. However, larger boilers typically come with higher installation costs. If you choose a unit that's too big, it may cycle on and off frequently, diminishing efficiency and increasing wear. Conversely, an undersized boiler struggles to meet demand, leading to additional costs. Balancing size with efficiency is essential for long-term savings.

Are There Financing Options for Purchasing a Boiler?

When considering boiler affordability, you'll find several financing options available to ease the upfront costs. Many companies offer payment plans, allowing you to spread the expense over time. Additionally, you might explore loans or rebates through government programs aimed at energy efficiency improvements. By researching these financing options, you can make a more informed decision and guarantee your boiler fits within your budget while still meeting your heating needs effectively.

What Are the Warranties Typically Offered on Boilers?

When considering boiler warranties, you'll find various options that typically range from one to ten years. Most warranties cover parts like the heat exchanger and certain components, but specific warranty coverage can vary by manufacturer. It's essential to review the terms carefully, as some warranties require regular maintenance to remain valid. Understand what's included to avoid unexpected costs down the line, ensuring you make an informed decision for your heating needs.

How Often Should I Replace My Boiler?

You should replace your boiler when it shows clear signs of aging or inefficiency, typically around 15 to 20 years. A boiler's lifespan varies, but if you notice frequent breakdowns, rising energy bills, or inconsistent heating, it's time to reflect on replacement. Regular maintenance can extend its life, but don't ignore those replacement signs. An outdated boiler can lead to safety hazards and increased costs, making timely replacement essential for your home's efficiency.

Can I Install a Boiler Myself to Save Costs?

You might consider DIY installation to save costs, but it's essential to assess your skills and local regulations. Installing a boiler involves complex plumbing and electrical work that requires expertise. Mistakes can lead to safety hazards and costly repairs. Instead of taking risks, weigh the potential savings against the possibility of future expenses. Hiring a professional guarantees compliance with safety standards and assures a reliable installation, which might be a smarter cost-saving measure in the long run.

Summary

In conclusion, the most expensive part of a boiler often hinges on the heat exchanger and burner due to their critical roles in efficiency and functionality. While controls and installation costs also contribute considerably, neglecting long-term maintenance can lead to even greater expenses down the line. By understanding these components and their associated costs, you can make informed decisions that enhance your boiler's performance and longevity, ultimately saving you money in the long run.