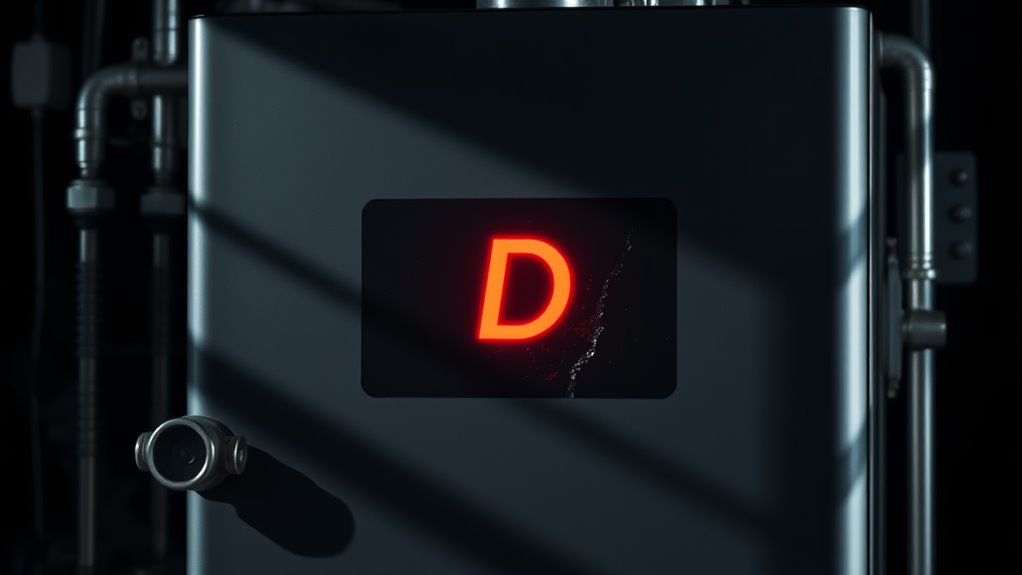

The 'D' indicator on your boiler usually means it's in diagnostic mode, signaling that the system is performing self-checks or addressing specific operational settings. This light can turn on due to low water pressure, a faulty pressure sensor, or other issues affecting performance. It's crucial to check your boiler's manual for precise meanings. Understanding what 'D' signifies can help you maintain boiler efficiency and prevent future problems. Learn more about troubleshooting and maintenance tips next.

Key insights

- The 'D' indicator typically signifies diagnostic mode or a special operational setting in a boiler.

- Activation of 'D' may indicate issues like low water pressure or a faulty pressure sensor.

- The meaning of 'D' can vary by brand; consult the user manual for specifics.

- Unexpected 'D' activation might suggest the need for maintenance or inspection of the boiler.

- Common troubleshooting involves checking pressure gauges, inspecting sensors, and bleeding radiators.

Understanding Boiler Indicators

Have you ever wondered what the various indicators on your boiler mean? Understanding boiler symbols is essential for maintaining efficiency and safety. Each symbol conveys specific information about the system's status. For instance, a steady green light typically indicates normal operation, while a red light can signal a fault or shutdown. Other indicators might display pressure levels, temperature, or maintenance reminders. Familiarizing yourself with these indicator meanings helps you diagnose issues before they escalate. Regularly checking these symbols guarantees your boiler runs smoothly and reduces the risk of costly repairs. By taking the time to learn what each indicator represents, you empower yourself to take proactive steps in maintaining your heating system effectively. Additionally, knowing how to interpret common error codes can significantly aid in troubleshooting boiler issues.

The Significance of 'D' on Your Boiler

The 'D' indicator on your boiler typically signifies a diagnostic mode or a specific operation setting, depending on the manufacturer. Understanding the indicator meanings can enhance boiler safety and guarantee peak performance. Here are four key points to reflect on about the 'D' indicator:

- Diagnostic Mode: It may indicate the boiler is in a self-check or troubleshooting mode.

- Operational Setting: In some models, 'D' could represent a default or special operational setting.

- Manufacturer Variations: The meaning of 'D' can differ across brands; always refer to the user manual.

- Safety Alerts: If 'D' activates unexpectedly, it may signal a need for maintenance or inspection.

Additionally, it is crucial to ensure that your boiler is regularly inspected by a Gas Safe registered engineer, as this helps maintain safety and compliance with gas regulations. Recognizing these aspects helps you maintain your boiler's efficiency and safety.

Common Causes for 'D' Indicator Activation

When your boiler's 'D' indicator activates, it often points to specific issues requiring attention. Common causes include low water pressure, a faulty pressure sensor, or air trapped in the system. You might also encounter common error messages related to ignition failure or overheating. To address these problems, start with basic troubleshooting techniques. Check the pressure gauge and verify it's within the recommended range, typically between 1 and 1.5 bar. If the pressure is low, you can safely add water to the system. Inspect the pressure sensor and look for any signs of malfunction. Finally, bleed radiators to release trapped air. By following these steps, you can diagnose and resolve the issues indicated by the 'D' light effectively. Additionally, regular inspections by qualified engineers can help identify issues early and prevent activation of the 'D' indicator.

Impacts of 'D' on Boiler Efficiency

The 'D' indicator on your boiler can markedly affect its efficiency rating. When activated, it often leads to increased energy consumption, impacting overall operational costs. Understanding these implications helps you optimize performance and maintain energy efficiency. Regular commercial boiler service ensures that any issues related to the 'D' indicator are addressed promptly, promoting optimal functionality.

Efficiency Rating Impact

Understanding how a 'D' rating affects boiler efficiency is essential for making informed decisions about heating systems. A boiler with a 'D' rating typically indicates lower energy savings and performance. Here's how it impacts your boiler's efficiency:

- Lower Boiler Performance: A 'D' rated boiler operates less effectively, requiring more fuel to produce the same heat.

- Increased Energy Costs: You'll likely face higher utility bills due to inefficient energy use.

- Limited Features: Often, 'D' rated boilers lack advanced technologies that enhance efficiency.

- Environmental Impact: Less efficient boilers contribute to higher carbon emissions.

Opting for a higher-rated boiler can lead to significant energy savings and better overall performance. Additionally, investing in energy-efficient heating systems can help reduce operational costs and support sustainability goals.

Energy Consumption Considerations

Even though a boiler with a 'D' rating may seem like a more affordable option initially, you'll soon notice the negative impact on energy consumption. Boilers with lower efficiency ratings consume more fuel to produce the same amount of heat, leading to higher operational costs. When you consider different fuel types, such as natural gas or oil, the disparity in energy efficiency becomes even more pronounced. A 'D' rated boiler may struggle to convert fuel into usable energy effectively, wasting resources and increasing your carbon footprint. Over time, the savings from an initial lower price are often eclipsed by higher energy bills. Investing in a higher-rated boiler can greatly enhance your energy efficiency and reduce long-term costs. Additionally, regular preventative maintenance ensures that your boiler operates at peak efficiency, further lowering energy consumption and costs.

Troubleshooting Steps for 'D' Indicators

When you see a 'D' indicator on your boiler, it often signals a specific issue that needs addressing. To effectively manage this situation, follow these boiler troubleshooting steps:

- Check the Pressure: Confirm the system pressure is within the recommended range; low pressure can trigger the 'D' indicator.

- Inspect the Thermostat: Verify that the thermostat is functioning correctly and set to the desired temperature.

- Examine the Valves: Look for any closed or obstructed valves that may disrupt the flow of water or steam.

- Review the Error Codes: Consult your boiler's manual to understand the specific indicator meanings related to the 'D' signal. Regular maintenance helps prevent error codes and enhances boiler longevity.

Addressing these items can help restore your boiler's operation efficiently.

When to Call a Professional

If you've followed the troubleshooting steps and the 'D' indicator persists, it's time to call a professional. Ignoring this warning can lead to further complications or safety hazards. Professional services can accurately diagnose the issue, ensuring your boiler operates efficiently and safely. Whether it's a malfunctioning component or a system failure, a technician has the expertise to handle emergency repairs effectively. Don't attempt to fix complex problems yourself, as this could exacerbate the situation or void warranties. Promptly contacting a professional not only saves you time but also helps avoid costly repairs down the line. Prioritize your safety and the longevity of your boiler by seeking expert assistance when needed. Additionally, consider scheduling regular preventative maintenance to ensure all components function smoothly and to reduce the likelihood of future issues.

Preventative Measures to Avoid 'D' Activation

To prevent 'D' activation on your boiler, establish a regular maintenance schedule to guarantee all components function properly. You should also monitor pressure levels consistently and inspect safety valves for any signs of wear or malfunction. Taking these steps can greatly reduce the risk of triggering a safety lockout. Additionally, regular inspections of your system can help identify potential issues before they escalate.

Regular Maintenance Schedule

A regular maintenance schedule is essential for preventing 'D' activation on your boiler. By adhering to a systematic plan, you can guarantee peak performance and safety. Here's a maintenance checklist to keep in mind:

- Conduct regular inspections to identify any wear and tear.

- Clean the boiler and its components to prevent blockages.

- Check and replace filters regularly to maintain airflow.

- Test safety devices to guarantee they function properly.

Following this maintenance checklist will help you avoid unexpected issues and prolong your boiler's lifespan. Schedule these tasks consistently, and you'll minimize the risk of 'D' activation, keeping your system running efficiently. Additionally, consider regular maintenance to enhance overall heating system efficiency and reduce energy costs. Remember, a well-maintained boiler is less likely to encounter problems.

Monitor Pressure Levels

Regular maintenance not only involves inspecting and cleaning your boiler but also monitoring pressure levels. You should regularly check the pressure gauge to guarantee it operates within the manufacturer's specified range. Employ monitoring techniques such as daily visual inspections and using digital pressure sensors for real-time tracking. If you notice fluctuations or abnormal readings, make pressure adjustments immediately to prevent 'D' activation. Familiarize yourself with the ideal pressure settings for your specific boiler model, as maintaining proper levels is vital for efficiency and safety. Consider documenting pressure levels over time to identify trends or recurring issues. By implementing these practices, you'll help make certain your boiler runs smoothly and minimize the risk of operational disruptions.

Inspect Safety Valves

Inspecting safety valves is essential for preventing 'D' activation in your boiler system. Regular safety valve inspection guarantees that your valves function correctly, maintaining system integrity. Here's how to perform a thorough valve performance evaluation:

- Visual Check: Look for physical damage or corrosion on the valves.

- Operational Test: Manually activate the valve to confirm it opens and closes smoothly.

- Pressure Testing: Verify that the valve opens at the correct pressure settings.

- Documentation Review: Check maintenance logs for previous inspections and repairs.

How to Interpret Other Boiler Indicators

How can you make sense of the various indicators on your boiler? Start by checking the boiler pressure gauge. It should typically read between 1 and 2 bar. If it's too low, your system may not function properly; too high, and you risk damage. Next, pay attention to the indicator lights. A green light usually signals normal operation, while a red light indicates a fault or safety issue requiring immediate attention. Yellow or orange lights might suggest maintenance is needed soon. Always consult your boiler's manual for specific indicators related to your model. Understanding these signals not only enhances your safety but also guarantees your boiler runs efficiently. Regular monitoring can prevent costly repairs down the line.

Maintaining Your Boiler for Optimal Performance

Understanding your boiler's indicators sets the foundation for effective maintenance. To guarantee your boiler operates at peak performance, follow these essential steps:

- Regular Inspections: Check for leaks, corrosion, and unusual noises.

- Boiler Cleaning Techniques: Implement proper cleaning methods to remove soot and debris, enhancing efficiency.

- Energy Efficiency Upgrades: Consider installing programmable thermostats or high-efficiency components.

- Scheduled Servicing: Arrange for a professional service annually to keep all systems in check.

Frequently Asked Questions

Can I Reset the 'D' Indicator Myself?

Yes, you can reset the 'd' indicator yourself, but it's essential to follow proper reset procedures. First, make certain you've turned off the power to the boiler for safety. Check the user manual for specific steps related to your model. After resetting, monitor the system closely for any irregularities. If issues persist, it's best to consult a professional. Always prioritize safety precautions when working with boiler systems to prevent accidents.

Does the 'D' Indicator Mean My Boiler Is Broken?

The 'D' indicator doesn't necessarily mean your boiler's broken, but it can signal an issue. Start by diagnosing issues based on the manual or troubleshooting tips provided by the manufacturer. Check for common problems like low pressure or blockages. If you're unsure, it's wise to consult a professional. Ignoring the indicator could lead to further complications, so addressing it promptly is vital for your boiler's efficiency and safety.

How Often Does the 'D' Indicator Activate?

The 'd' indicator activates based on specific conditions within your boiler's operation. Typically, you might notice it lighting up during periods of high demand or when the system detects an issue. The activation patterns can vary widely depending on usage frequency, maintenance, and system efficiency. If the indicator frequently activates, it could signal underlying problems that require immediate attention to guarantee your boiler operates smoothly and safely.

Will Ignoring the 'D' Indicator Cause More Damage?

Ignoring the 'd' indicator can definitely lead to more damage. If you don't address the issue promptly, you risk overheating or system failure, which can escalate repair costs. Regular boiler maintenance tips suggest monitoring indicators closely to avoid potential damage risks. Guarantee you're familiar with the signals your boiler gives and take action when necessary. Staying proactive can save you from costly repairs and extend the lifespan of your boiler.

What Should I Do if the 'D' Indicator Blinks?

If the 'd' indicator blinks, you should immediately check your boiler's manual for troubleshooting guidance. It often signals an issue that needs addressing. Follow these boiler maintenance tips: guarantee the pressure is adequate, check for error codes, and inspect connections. If you can't resolve the issue, it's best to contact a professional. Regular maintenance can prevent future problems, so keep your boiler in top condition to avoid unnecessary breakdowns.

Summary

In summary, understanding the 'D' indicator on your boiler is essential for maintaining efficiency and safety. When it activates, it signals potential issues that need your attention. By following troubleshooting steps and implementing preventative measures, you can minimize disruptions. Always remember, if you're uncertain or the problem persists, don't hesitate to call a professional. Regular maintenance will further enhance your boiler's performance, ensuring it runs smoothly and effectively for years to come.